What is sourcing service?

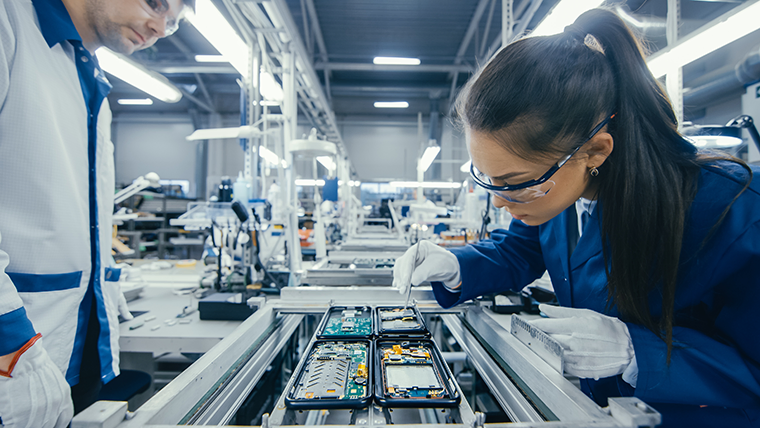

Sourcing service refers to the process of identifying, evaluating, and partnering with the right manufacturers to ensure product quality, cost-efficiency, and on-time delivery.

With over 20 years of experience in manufacturing consumer electronics, EILI is not only a trusted OEM/ODM supplier but also a reliable sourcing partner — helping clients quickly connect with qualified factories in Vietnam, China, and Cambodia.

We manage the end-to-end sourcing process — from factory identification and qualification to price negotiation, sampling, quality inspection, and production tracking — to ensure smooth, efficient, and reliable supply.